The Direct to Film, or DTF printing process provides the ability to create t-shirts, hoodies, and tote bags with unlimited colors and great quality. The designs are long-lasting, with the vivid colors staying true through multiple washes. DTF printing technology has experienced rapid growth, gaining tremendous popularity as an alternative to traditional screen printing methods.

While DTF printers produce more professional results than many other printing methods, most people don’t find the specialized equipment very cost-effective. The direct-to-film printer – and the curing oven to set the design – can run in the thousands.

Besides the printer, DTF supplies needed include transfer films and inks, which need to be compatible with printers to ensure high-quality prints. Some consumers purchase the special film using online DTF gang sheet builders, but the design tools can be complicated, with no clear instructions.

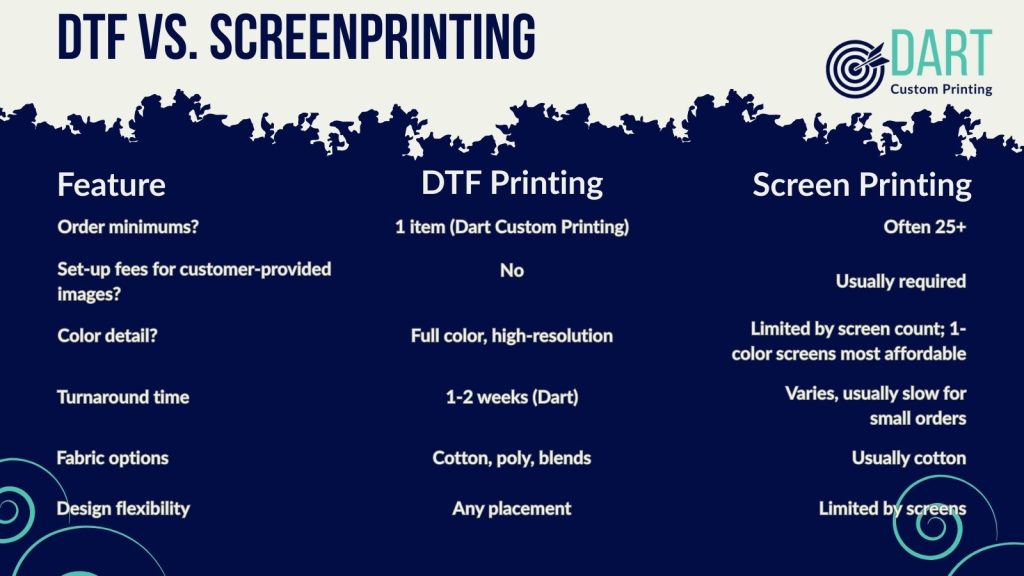

DTF printing has undoubtedly revolutionized the brand logo apparel printing industry by enabling small print shops like Dart Custom Printing to offer full-color, high-quality designs with vivid details. At our boutique t-shirt printing shop near Aulander, that also means no minimums to start the ordering process.

Once your design is approved, it’s time for professional printing onto specialized film and prepped for transfer. First, a PET film is prepared and placed in the DTF printing machine where the design will be printed in color.

After creating a first layer, the machine prints a white layer over the whole image. An adhesive powder is uniformly applied onto the wet ink. After applying the powder, the film is heated in a curing oven to prepare for fabric transfer.

The film prep step ensures your artwork is crisp, vibrant, and ready to be applied to your chosen garment or item with precision.

Using a heat press machine, we embed the DTF film onto your chosen item using high heat and precision. The fabric receiving the DTF transfer is dehumidified and pre-flattened under a heat press. The design on the film is transferred onto the fabric using a heat press for 20 seconds.

After pressing the transfers/prints, the film is hot peeled immediately after the transfer is complete. Finally, the designed fabric is flattened a second time in the heat press to improve durability.

The result? A crisp, durable print that holds up wash after wash.

If you’re looking for:

Custom t-shirt printing in NC (or anywhere in the US)

A modern printing method with no setup fees

Fast turnaround and flexible order sizes

A local shop that listens to your needs

Then yes—DTF is your new best friend. The Dart Custom Printing team is happy to help. Our customers speak about the quality of our pet films and their finished apparel all the time.

Your custom apparel looks amazing—let’s keep it that way. DTF prints are durable, but a little care goes a long way in preserving color, detail, and longevity.

Here’s how to treat your gear right to keep it looking great, wash after wash:

Wash Inside Out

Protect the print by turning garments inside out before washing. It’s like a little shield for your design.

Cold or Warm Water Only

Skip the hot water—it’s tough on prints and fabric alike.

Gentle Cycle Preferred

Your custom t-shirt isn’t training for a triathlon. Keep the spin cycle chill.

No Bleach or Harsh Detergents

These chemicals are print killers. Stick to mild detergents.

Hang Dry or Low Heat

High heat can shorten your print’s lifespan. Air drying is best, but low-medium tumble dry works too.

Avoid Ironing Directly on the Print

If you must iron, place a cloth over the design or iron inside out. Or just embrace the wrinkle—it’s character.

Direct-to-film printing uses a special printed film that’s transferred onto your shirt with heat, allowing for vivid, durable designs on a wide range of materials.

Unlike vinyl or screen printing, the detail is sharper and the colors last longer. The print quality provided by the DTF process is incredible.

We use professional-grade transfer film that holds color well and ensures your design presses cleanly onto the shirt. This gives you sharp lines, solid fills, and long-lasting wear.

Yes, our transfer prints are made to last through many washes without fading or cracking. When cared for properly, they stay looking fresh for a long time.

Yes! Our process involves printing your design onto PET film before transferring it onto your chosen fabric. This step helps ensure consistent results every time.

Yes—we stock professional-quality DTF transfer films designed for smooth application, sharp colors, and long-lasting durability across different fabric types.

Our main printing technique is the printer DTF method, which uses CMYK colors and fine detail to create designs that are pressed directly onto apparel and other items.

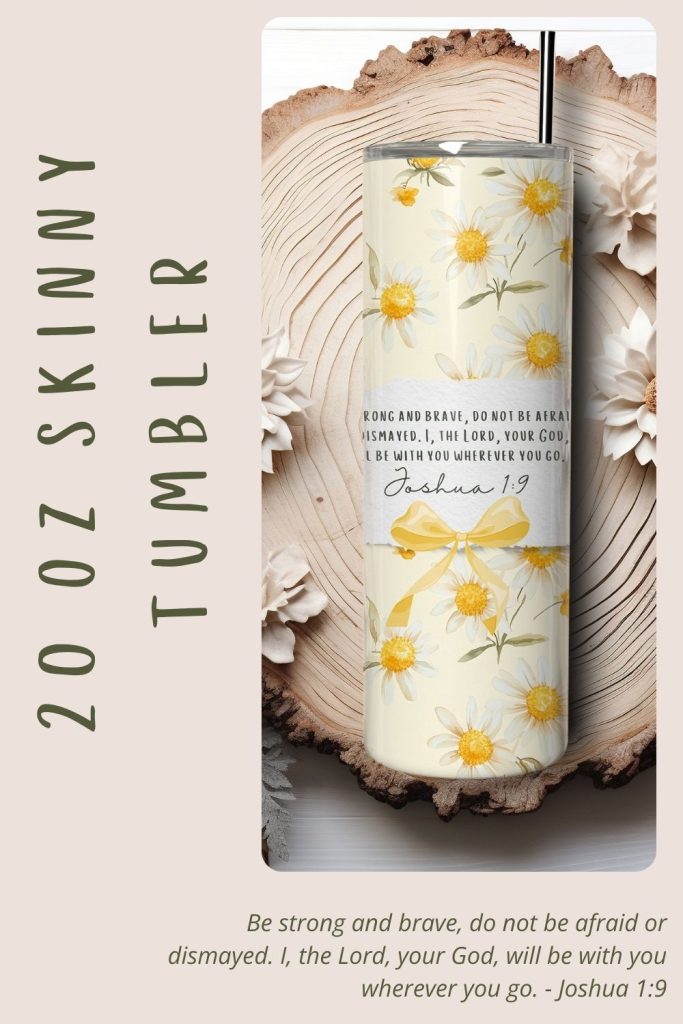

Yes! We can print on a wide array of materials, including cotton fabrics and poly blends, making DTF transfer printing versatile for nearly any project. If you have other substrates in mind – coffee mugs, tumblers, etc. – just ask. We offer sublimation printing in addition to our custom pet film dtf transfers.

Yes—we offer sublimation printing alongside DTF. Sublimation is perfect for polyester and specialty items like tumblers, while DTF is ideal for cotton and blends.

We focus on high quality DTF printing by using premium inks, CMYK colors, and a precise heat press mechanism that locks your design into place with accuracy and vibrancy.

Yes! With our DTF gang sheet builder, you can arrange multiple designs onto one sheet for maximum efficiency and cost savings on larger orders.

Your artwork is printed onto film, then applied to the intended surface (like a shirt or tote) using a heat press mechanism. The transfer ensures the design bonds tightly to the fabric for long-lasting wear.

Custom t-shirts, hoodies, tumblers, and more—printed locally in Eastern NC with fast turnaround and with no minimum order.